AI-Powered Quality Assurance in Manufacturing

A leading automotive parts manufacturer in Dubai Industrial City was facing critical quality control issues with their brake component production line. Manual inspection of 50,000+ brake pads daily resulted in a 12% defect rate reaching customers, causing warranty claims worth AED 8.5M annually. The inspection process required 24 quality control staff working in shifts, creating bottlenecks during peak production periods.

The Challenge

A leading automotive parts manufacturer in Dubai Industrial City was facing critical quality control issues with their brake component production line. Manual inspection of 50,000+ brake pads daily resulted in a 12% defect rate reaching customers, causing warranty claims worth AED 8.5M annually. The inspection process required 24 quality control staff working in shifts, creating bottlenecks during peak production periods.

Our Solution

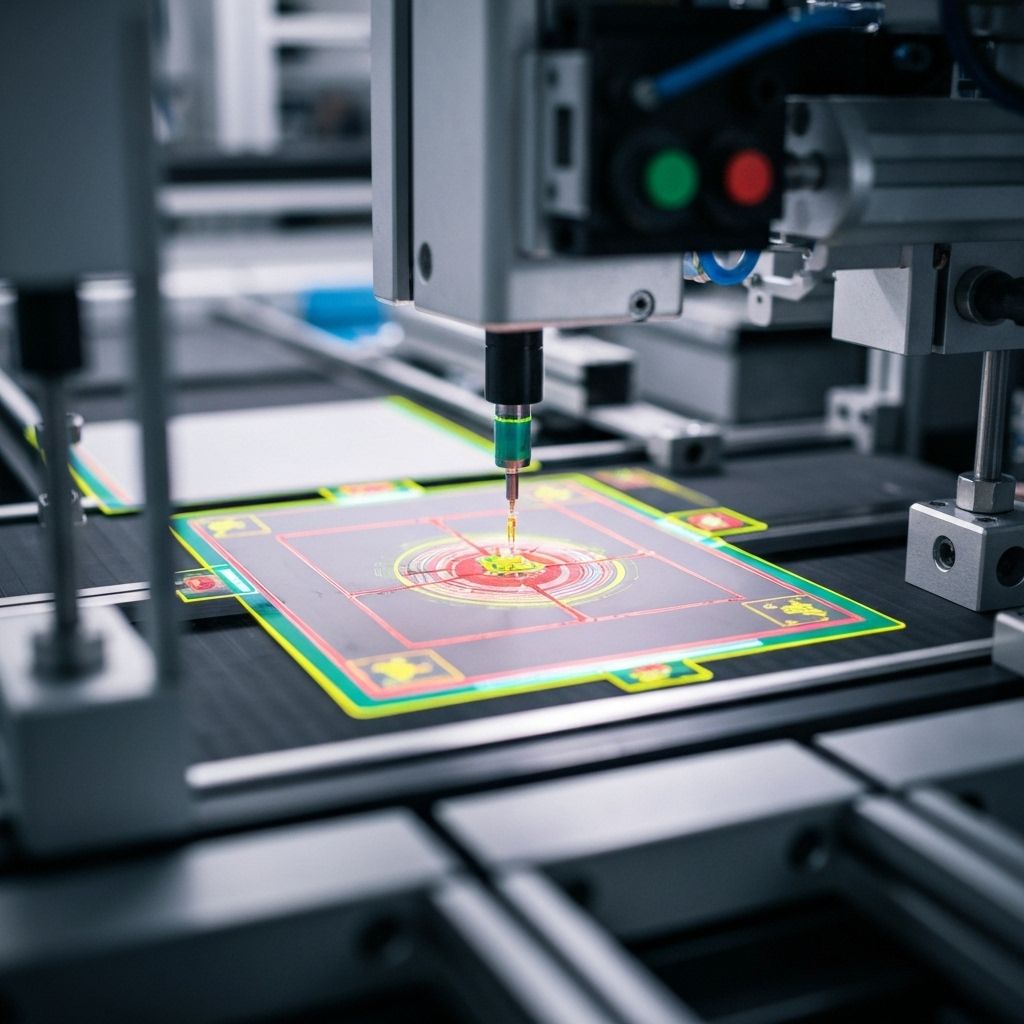

We implemented a comprehensive computer vision solution that transforms the existing production line cameras into an intelligent quality assurance system. Our custom CNN models were trained on 150,000 brake pad images, including 25,000 defect samples covering surface cracks, dimensional variations, material inconsistencies, and coating defects. The system processes images at 60 FPS, analyzing each brake pad for 47 different quality parameters within 0.8 seconds per unit.

Implementation Steps

- Upgraded 8 existing production line cameras to 4K resolution with specialized lighting

- Deployed NVIDIA Jetson AGX Xavier edge computing units for real-time processing

- Trained custom ResNet-50 models on 150,000 brake pad images with defect annotations

- Integrated pneumatic rejection system triggered by AI detection results

- Connected to existing SAP ERP system for quality tracking and reporting

- Implemented real-time dashboard showing defect rates, production metrics, and trend analysis

Project Gallery

"The AI quality control system has revolutionized our production line. We've eliminated human error in inspection while dramatically increasing our throughput. The ROI was achieved within 8 months of deployment."

Project Details

Technologies Used

Ready for Similar Results?

Let's discuss how we can transform your business with AI